กลุ่มอุปกรณ์เป่าลม โบลเวอร์ (Industrial Fan & Blower)

Product

Menu

CUSTOMER CENTER

FAX

แฟกซ์

02-869-6070

อีเมล

fluid.fms@gmail.com

fluid.fms@gmail.com

LINE

ไลน์.

@fluidmechanic

กลุ่มอุปกรณ์เป่าลม โบลเวอร์ (Industrial Fan & Blower)

หัวข้อ

MAGNETIC LEVITATION TURBO BLOWER

Magnetic levitation bearing turbo blower

is widely used in waste water treatment, oil, metallurgy medicine, coal, chemical, textile, printing, food, cement, electric power and some other industries, for aeration, pressure rising, pneumatic conveying, drying, extraction and purification, vacuum pressure package, solution recovery, gas phase separation and other process.

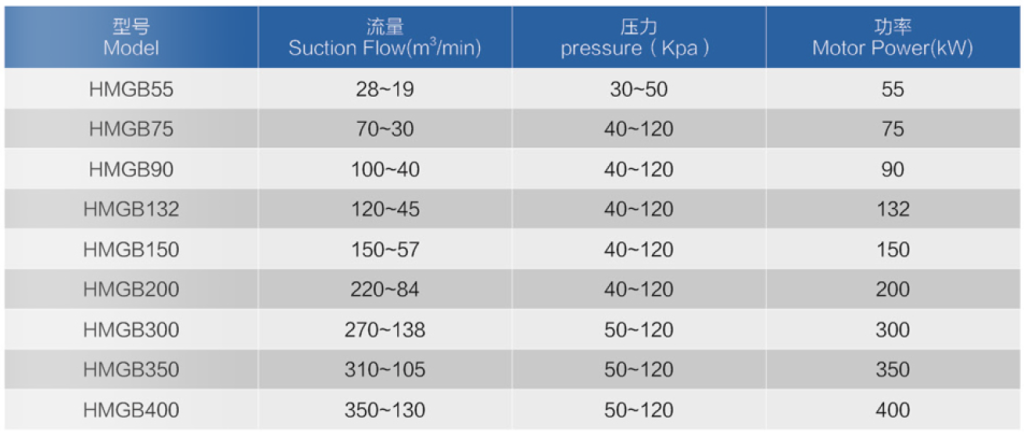

PRESSURE: 30-120KPa

CAPACITY: 19-350m3/min

FEATURE: ENERGY SAVING, LOWER NOISE LEVEL, MAGNETIC LEVITATION BEARING

CAPACITY: 19-350m3/min

FEATURE: ENERGY SAVING, LOWER NOISE LEVEL, MAGNETIC LEVITATION BEARING

คุณสมบัติสำคัญ

1. High efficiency and profitability

*self-designed high efficiency centrifugal impeller high efficiency permanent magnet synchronous motor drive.

*30% higher efficiency than volumetric roots blowers.

*20% more efficient than multi-stage centrifugal fans.

*15% higher efficiency compared to gear-speed single-stage centrifugal fans.

*self-designed high efficiency centrifugal impeller high efficiency permanent magnet synchronous motor drive.

*30% higher efficiency than volumetric roots blowers.

*20% more efficient than multi-stage centrifugal fans.

*15% higher efficiency compared to gear-speed single-stage centrifugal fans.

2. No needs of lubrication and mechanical maintenance.

Due to the use of advanced magnetic levitation bearing technology, the complicated gear boxes and oily bearings necessary for traditional blower are eliminated, so there is no lubricant, no mechanical maintenance, reduced emissions of waste oil and other pollutants, and reduced operating costs. Improve the stability and reliability of the entire system under production conditions.

Due to the use of advanced magnetic levitation bearing technology, the complicated gear boxes and oily bearings necessary for traditional blower are eliminated, so there is no lubricant, no mechanical maintenance, reduced emissions of waste oil and other pollutants, and reduced operating costs. Improve the stability and reliability of the entire system under production conditions.

3. Low vibration and noise level.

Due to the use of an advanced magnetic suspension bearing system and integrated soundproof cover, the rotating parts have no contact with the mechanical system, no mechanical friction, stable operation, low vibration, and the whole machine noise is less than 85 decibels. Efficient, quiet, environmental friendly, flexible and easy to install

Due to the use of an advanced magnetic suspension bearing system and integrated soundproof cover, the rotating parts have no contact with the mechanical system, no mechanical friction, stable operation, low vibration, and the whole machine noise is less than 85 decibels. Efficient, quiet, environmental friendly, flexible and easy to install

4. Easy to installation and maintenance.

*Magnetic levitation high speed centrifugal blower is light weight, small size, beautiful appearance, touch screen control, easy operation.

*Routine maintenance only needs to replace the air filter, which is convenient and simple, saving equipment maintenance costs

*Magnetic levitation high speed centrifugal blower is light weight, small size, beautiful appearance, touch screen control, easy operation.

*Routine maintenance only needs to replace the air filter, which is convenient and simple, saving equipment maintenance costs

สอบถามข้อมูลเพิ่มเต็ม และขอcatalogสินค้า กรุณาติดต่อเจ้าหน้าที่ฝ่ายขายได้ที่ 02-8696061-9